Table of Contents

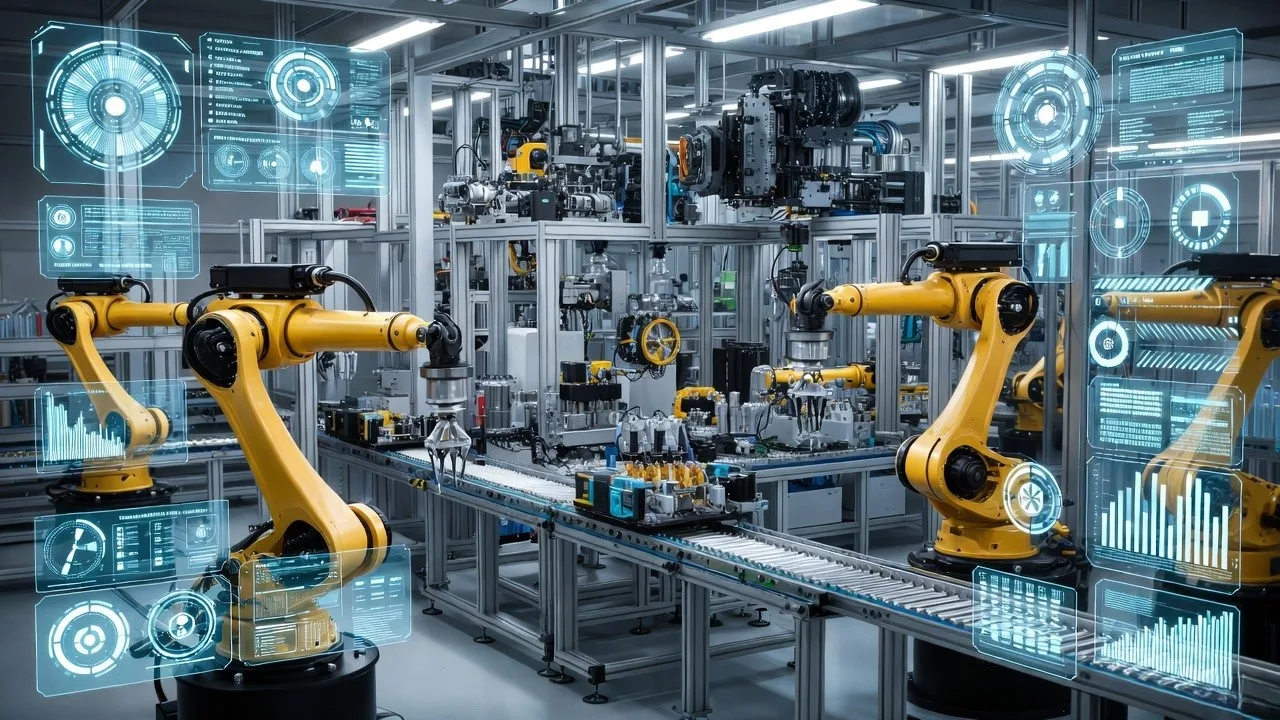

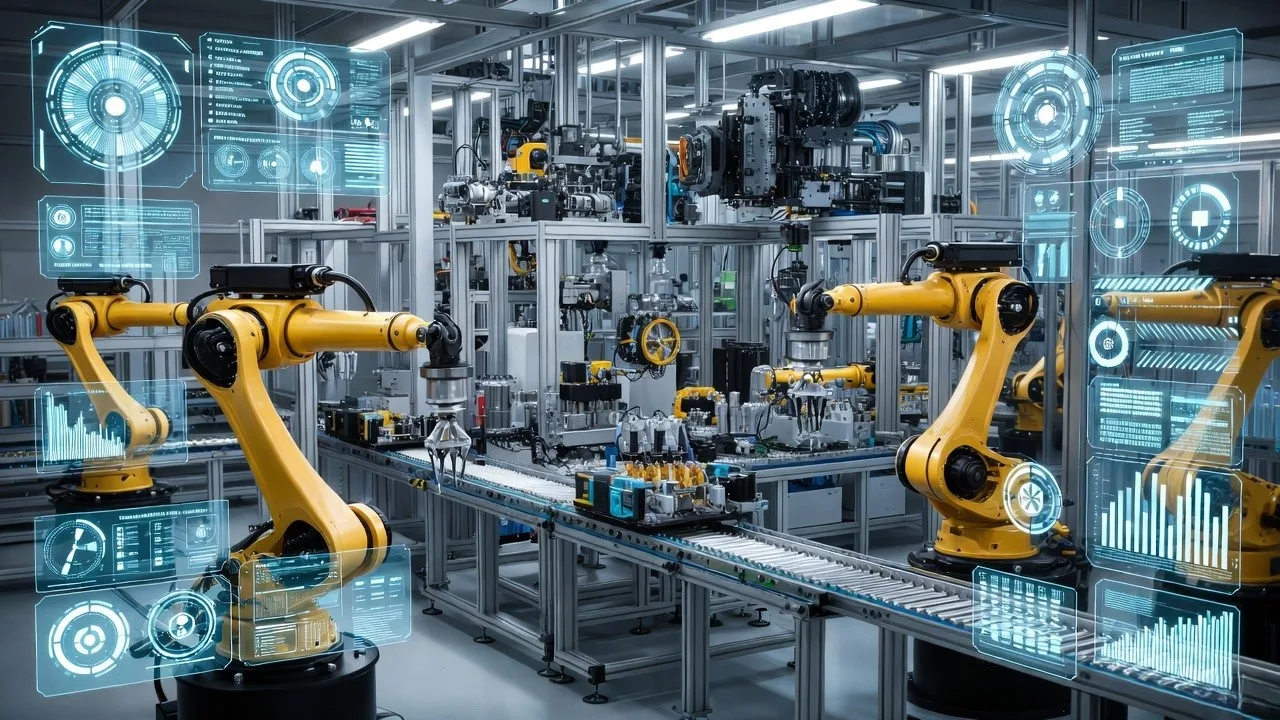

Smart Factory Revolution: How AI Agents Are Powering the Next Generation of Automated Manufacturing

In a Midwestern automotive parts factory, a critical conveyor belt motor shows the faintest vibration anomaly at 2:37 AM. Before any human could notice, an AI agent has already diagnosed the impending failure, dispatched a work order to maintenance, and rerouted production through alternate lines all by 2:39 AM. This isn’t science fiction; it’s the reality manufacturers are achieving through AI-powered automation.

At Nunar, we’ve deployed over 500 specialized AI agents in production environments, witnessing firsthand how this technology transforms operations from reactive to predictive. For U.S. manufacturers facing unprecedented labor shortages and global competition, AI agents have become the indispensable engine of modern automated manufacturing systems.

AI agents are sophisticated software entities that perceive their environment, process information, make decisions, and act autonomously to optimize manufacturing processes, representing the next evolution beyond traditional automation.

⚙️ Free Guide: “How to Use AI to Automate Your Manufacturing Operations”

Learn the exact framework our clients use to cut downtime, optimize production flow, and improve decision accuracy with AI-powered automation.

👉 Download the GuideWhat Are AI Agents and How Do They Differ from Traditional Automation?

Understanding the distinction between AI agents and conventional automation is crucial for manufacturers considering digital transformation. While traditional automation follows predefined rules and fixed workflows, AI agents introduce intelligence, adaptability, and autonomous decision-making to manufacturing environments.

Traditional automation in manufacturing typically consists of programmed systems that perform repetitive tasks with high precision but limited flexibility. These systems excel in controlled environments where variables remain constant, but struggle when conditions change or unexpected situations arise. They can’t learn from experience or improve their performance without human intervention.

AI agents fundamentally differ through several core capabilities:

- Autonomy: AI agents can operate independently within defined parameters, making decisions without constant human oversight

- Adaptability: Unlike static automation, AI agents learn and improve over time, refining their performance based on new data and changing conditions

- Proactive Problem-Solving: They anticipate issues before they occur through pattern recognition and predictive analytics

- Contextual Understanding: AI agents can process multiple data streams simultaneously to make informed decisions in complex environments

In practice, this means an AI agent doesn’t just mindlessly execute the same welding pattern thousands of times—it adjusts the weld in real-time based on material variations, predicts when the welding tip needs replacement, and identifies subtle quality issues invisible to the human eye. This represents a paradigm shift from doing things right to learning what’s right to do.

The Manufacturing Landscape in 2025: Why AI Agents Are No Longer Optional

The North American manufacturing sector stands at a critical juncture. Between 2025 and 2034, the global industrial automation market is projected to grow at a CAGR of 9.31%, reaching approximately USD 569.27 billion by 2034 . This growth isn’t driven by technological fascination alone, but by pressing operational necessities.

Several converging factors make AI agent adoption essential for competitive U.S. manufacturing:

- Labor shortages and skills gaps: The manufacturing sector faces a critical shortage of specialized workers, with 80% of small and mid-sized manufacturers expressing concern about workforce capabilities

- Supply chain vulnerabilities: 75% of companies reported significant supply chain disruptions in recent years, highlighting the need for more resilient, adaptive operations

- Efficiency demands: With margins constantly squeezed, manufacturers must achieve new levels of operational efficiency while maintaining quality standards

- Customization pressure: Consumers increasingly demand personalized products, requiring manufacturing systems capable of handling high-mix, low-volume production

The Asia Pacific region currently leads in industrial automation adoption, accounting for over 39% of the global market share . For U.S. manufacturers to maintain competitiveness, embracing AI-driven automation isn’t strategic—it’s existential. Companies that implement AI agents effectively are seeing dramatic improvements: up to 40% reduction in unplanned downtime, 30% increases in quality control accuracy, and significant decreases in operational costs.

🧠 Ready to Explore Smart Automation?

Get a personalized roadmap on how AI agents and GPT-powered systems can streamline your manufacturing processes.

👉 Book a Free 20-Minute Strategy SessionKey Applications of AI Agents in Automated Manufacturing Systems

Based on our deployment of over 500 AI agents across U.S. manufacturing facilities, we’ve identified several high-impact application areas where this technology delivers transformative results.

Predictive Maintenance and Downtime Reduction

Unplanned equipment failure remains one of the most significant costs in manufacturing, often halting production and requiring expensive emergency repairs. AI-powered predictive maintenance agents analyze real-time data streams from sensors—vibration, temperature, pressure, acoustics—to identify subtle patterns indicative of developing faults .

These agents don’t just detect anomalies; they predict potential failures with remarkable accuracy before they occur, then automatically generate work orders or alerts for proactive maintenance. In one deployment for a food processing plant, our predictive maintenance agent forecast a critical compressor failure 47 hours before it would have occurred, preventing 12 hours of production downtime and saving an estimated $180,000 in lost productivity and emergency repairs.

AI-Driven Quality Control and Defect Detection

Manual inspection processes are often slow, expensive, and prone to human error, while hidden defects can lead to significant scrap, rework, recalls, and reputational damage. AI visual inspection agents, trained on specific products and defect typologies, analyze images or sensor data in real-time with superhuman accuracy .

These systems identify subtle flaws, inconsistencies, or deviations from specification that human inspectors might miss. In an electronics manufacturing application, one of our computer vision agents detected microscopic circuit board soldering defects with 99.7% accuracy, reducing customer returns by 34% in the first quarter of implementation. The agent continuously improves its detection capabilities as it processes more examples, becoming increasingly precise over time.

Supply Chain Optimization and Resilience

Today’s global supply networks are intricate and highly vulnerable to disruption from supplier delays, geopolitical events, transportation bottlenecks, and sudden demand shifts. AI supply chain agents aggregate data from multiple sources—suppliers, logistics providers, internal systems, external news feeds—to proactively monitor risks and recommend mitigation strategies .

These agents provide unprecedented visibility and resilience, enabling manufacturers to anticipate and navigate disturbances more effectively. One of our deployments for an automotive parts manufacturer processes over 15,000 data points daily from suppliers, weather systems, port operations, and logistics providers, identifying potential disruptions an average of 12 days earlier than traditional methods and recommending alternative sourcing or routing strategies.

Autonomous Production Planning and Scheduling

Modern manufacturing requires balancing countless variables—machine availability, workforce capacity, material inventories, order priorities, and energy constraints. AI production planning agents continuously optimize this complex equation, dynamically adjusting schedules in response to changing conditions.

These agents can simulate multiple scheduling scenarios, predict their outcomes, and implement the optimal approach. In a discrete manufacturing environment, one of our scheduling agents increased overall equipment effectiveness (OEE) by 18% through intelligent batch sequencing, changeover optimization, and energy-aware production timing adjusting operations to leverage lower energy rate periods without compromising delivery deadlines.

Energy Management and Sustainability Optimization

With rising energy costs and increasing focus on corporate sustainability, AI agents are proving invaluable for reducing environmental impact while lowering operational expenses. These systems monitor energy consumption patterns across equipment, identify inefficiencies, and automatically implement conservation measures.

One of our deployments in a chemical processing plant uses an AI agent to optimize heating, cooling, and compression systems based on production schedules, weather forecasts, and real-time energy pricing. The system has achieved 23% energy reduction while maintaining output, contributing significantly to both environmental targets and the bottom line.

Table: Impact of AI Agents Across Manufacturing Process Automation

🚀 From Manual to Autonomous: The Next Leap in Manufacturing

Discover how manufacturers are deploying custom AI agents to transform efficiency, quality control, and production agility.

👉 See How It WorksImplementing AI Agents: A Practical Framework for U.S. Manufacturers

Successful AI agent implementation requires more than just technology acquisition—it demands strategic alignment with operational priorities and a phased approach to integration. Based on our experience deploying hundreds of agents, we’ve developed a framework that ensures maximum impact and return on investment.

Start with Specific, High-Impact Use Cases

The most successful AI implementations begin with narrowly defined problems that have measurable impact on operations. Rather than attempting enterprise-wide transformation simultaneously, identify specific processes where AI agents can deliver quick, demonstrable value.

We typically recommend starting with one of these proven entry points:

- Predictive maintenance for critical equipment with high downtime costs

- Quality control in processes with known defect issues

- Inventory optimization for high-value or long-lead-time components

These focused applications build confidence, generate quick wins, and develop organizational capability for broader implementation. For instance, our work with a aerospace components manufacturer began with a single AI agent focused on optimizing cutting tool replacement in CNC machines a limited scope that delivered 27% tool life extension and eliminated tool-related quality issues, paving the way for broader adoption.

Build Upon Existing Data Infrastructure

Many manufacturers delay AI initiatives over concerns about data readiness. While AI agents require data, they can often work with existing sources equipment sensors, ERP systems, quality management records, and production logs. The key is identifying accessible data streams and addressing critical gaps incrementally.

Most industrial facilities already generate vast amounts of untapped data. One study found that less than 1% of manufacturing data is currently utilized for decision-making . AI agents can extract value from this dormant asset. In one deployment, we integrated with legacy equipment using existing PLCs and SCADA systems, developing adapters that translated decades-old protocol data into usable insights for AI processing.

Prioritize Human-AI Collaboration

The most effective AI implementations augment human capabilities rather than replace them. Design AI agents to handle repetitive, data-intensive tasks while empowering employees with insights and recommendations for strategic decision-making.

This approach transforms roles rather than eliminates them. For example, maintenance technicians evolve from performing routine inspections to addressing prioritized, predicted issues becoming more productive and engaged in the process. One client found that their maintenance team’s job satisfaction increased significantly when freed from tedious inspection rounds to focus on solving complex technical problems identified by AI agents.

Plan for Scalability and Integration

While starting with focused applications, design AI agents with eventual integration in mind. Ensure they can communicate with other systems and agents, sharing insights and coordinating actions across the manufacturing ecosystem.

This might begin with a single predictive maintenance agent but should architecturally support future expansion to quality optimization, energy management, and supply chain coordination. Our most successful implementations follow a “modular but connected” approach deploying specialized agents for specific functions while maintaining the ability for these agents to share information and coordinate actions when beneficial.

The Future of AI in Automated Manufacturing: Emerging Trends

The evolution of AI in manufacturing is accelerating, with several key trends shaping the next generation of automated systems:

- Multi-Agent Systems: Instead of isolated AI applications, we’re moving toward coordinated ecosystems where specialized agents collaborate—production scheduling agents communicating with maintenance prediction agents and supply chain agents to optimize holistically

- Generative AI Integration: Beyond analytical capabilities, generative AI is being applied to design manufacturing processes, create digital twins, and generate troubleshooting guides for novel situations

- Edge Computing Convergence: The combination of 5G connectivity and edge computing enables real-time AI decision-making directly on the factory floor, reducing latency and cloud dependency

- Self-Optimizing Systems: The next frontier involves AI systems that not only identify optimization opportunities but implement and test improvements autonomously, creating continuous self-improvement cycles

As these trends converge, we’re progressing toward truly autonomous manufacturing environments where AI agents manage increasingly complex operations with minimal human intervention.

People Also Ask: Common Questions About AI in Automated Manufacturing

AI-powered predictive maintenance agents typically reduce unplanned downtime by up to 40% by identifying equipment issues before they cause failures . The exact impact varies by application, but most implementations show significant improvement in overall equipment effectiveness.

Traditional automation follows predefined rules rigidly, while AI agents perceive their environment, make decisions, learn from experience, and adapt to changing conditions autonomously . Think of the difference between a conveyor belt that moves at fixed speeds versus one that adjusts its operation based on real-time production needs and potential bottlenecks.

Reputable AI agent companies implement enterprise-grade security including advanced encryption, access controls, and compliance frameworks specifically designed for industrial environments . Security should be a primary consideration in selection and implementation.

The Path Forward for U.S. Manufacturers

The transformation from traditional to AI-powered automated manufacturing systems is no longer a future possibility it’s a present necessity for competitive relevance. The manufacturers thriving in today’s challenging environment aren’t those with the newest equipment or lowest labor costs, but those most effectively leveraging AI to optimize their operations.

Based on our experience deploying over 500 AI agents in production environments, the pattern is clear: incremental approaches deliver outsized returns. Starting with specific, high-impact use cases generates the momentum, expertise, and financial justification for broader transformation. The manufacturers who delay risk not just immediate efficiency penalties but accumulating capability gaps that become increasingly difficult to close.

For U.S. companies facing global competition, workforce challenges, and supply chain volatility, AI agents offer a path to resilience, flexibility, and sustained competitiveness. The question is no longer whether to implement AI-powered automation, but where to begin and how to accelerate.

At Nunar, we specialize in developing and deploying customized AI agents for manufacturing environments. Our team has helped dozens of U.S. manufacturers navigate this transformation, from initial assessment through full-scale implementation. If you’re considering how AI agents could transform your operations, contact us for a specific use case assessment tailored to your manufacturing environment.

NunarIQ — The All-in-One AI Agent Platform Driving Efficiency, Precision, and Growth

NunarIQ equips GCC enterprises with AI agents that streamline operations, cut 80% of manual effort, and reclaim more than 80 hours each month, delivering measurable 5× gains in efficiency.

Industries

- Logistics

- Retail

- Manufacturing

- Healthcare

- Finance

- Energy & Resources

Resources

- Blogs

- Whitepaper

- Knowledge Base

- AI Agent Requirement Analysis