Table of Contents

Beyond the Hype: How AI Agents Are Redefining U.S. Custom Industrial Automation

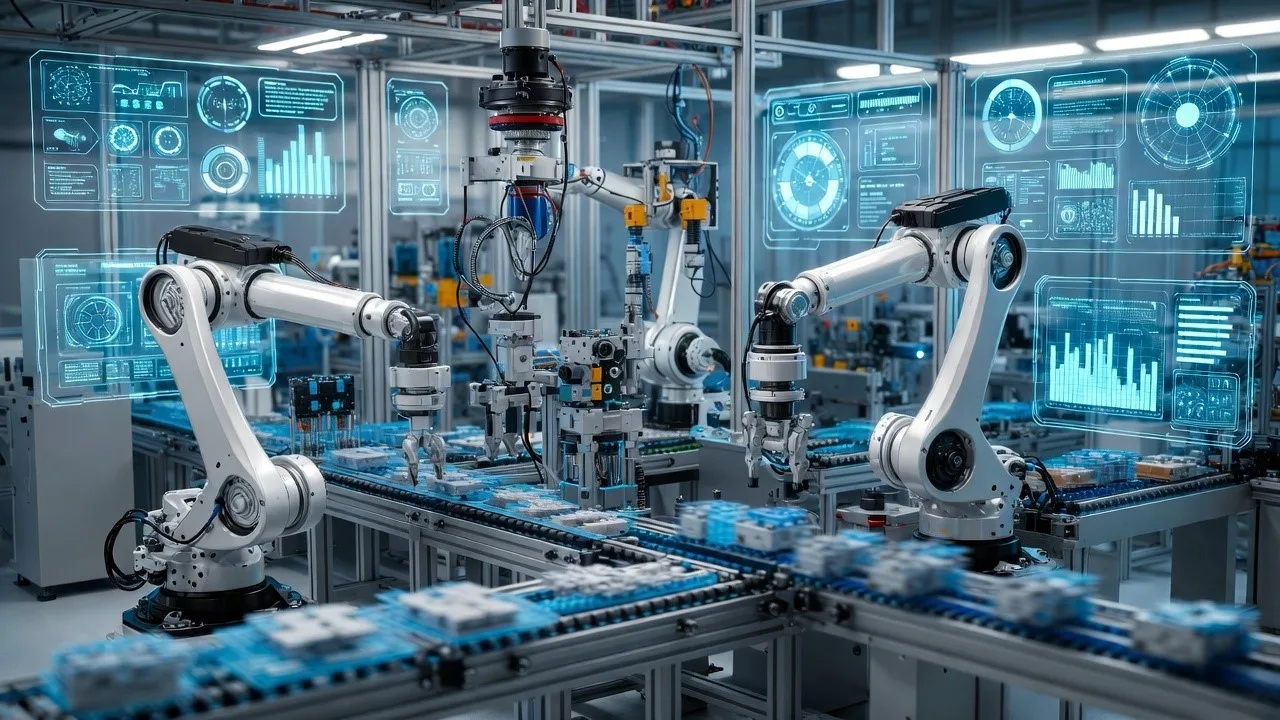

In a Midwest automotive plant, a single AI agent now orchestrates a symphony of robots, predicts a critical motor failure 48 hours before it happens, and automatically reroutes production—all without human intervention. A year ago, this would have been science fiction. Today, it’s a measurable competitive advantage. For U.S. manufacturers, the question is no longer if they should automate, but how to build an intelligent, adaptive operation that can compete on the global stage.

At Nunar, we’ve deployed over 500 AI agents into live production environments. This hands-on experience has shown us that the next leap in productivity won’t come from just faster machines, but from smarter, decision-making AI that integrates seamlessly into existing workflows. This new era moves beyond rigid, traditional automation to systems that learn, adapt, and optimize in real-time. For American factories, this isn’t just an upgrade; it’s a necessary evolution to tackle skilled labor shortages, complex supply chains, and intense global competition.

AI agents are transforming U.S. industrial automation by moving beyond simple task execution to autonomously manage complex workflows, predict maintenance needs, and optimize entire production lines for unprecedented efficiency and cost savings.

📘 Free Guide: “How to Build Custom Industrial Automation Solutions”

Learn the steps to design tailored automation workflows using AI, robotics, and smart factory technology.

👉 Download the GuideThe State of U.S. Industrial Automation: A Market Primed for AI

The U.S. industrial automation market is in a period of explosive growth, valued at USD 49.8 billion in 2024 and projected to reach USD 103.8 billion by 2032, growing at a robust CAGR of 9.8% . This surge isn’t happening in a vacuum. It’s a direct response to pressures that U.S. manufacturers know all too well: the need for resilience, the shortage of skilled labor, and government policies like reshoring incentives that make investing in domestic, high-tech production not just attractive, but strategically essential .

The manufacturing landscape is shifting from the traditional, rigid automation of the past to a more fluid, intelligent future. A key trend we’ve observed in hundreds of deployments is the rise of collaborative robots (cobots). Unlike their isolated predecessors, these robots are designed to work alongside human workers, taking over physically demanding or hazardous tasks while allowing their human counterparts to focus on more complex problem-solving and final assembly . This human-robot collaboration is crucial for maintaining engagement and improving overall operational efficiency.

Furthermore, the U.S. government is actively encouraging this transformation. Through tax benefits, grants, and funding, manufacturers are being supported to bring operations back to U.S. soil and implement advanced automation technologies . The goal is clear: build a more robust, self-reliant economy by decreasing dependence on international production and creating high-tech jobs at home. For U.S. manufacturers, this support helps offset the initial investment and accelerates the push towards smarter factories.

From Automation to Autonomy: The AI Agent Revolution

Traditional automation has long been based on a simple principle: “if X, then Y.” Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems excel at executing pre-defined, repetitive tasks. They are the backbone of the factory floor, but they have a critical limitation—they cannot handle the unexpected. If a situation occurs that wasn’t explicitly programmed, the system stops, and a human must intervene.

This is where AI agents mark a fundamental shift. An AI agent is an intelligent system that can perceive its environment, make decisions, and take actions to achieve specific goals without step-by-step human direction. Think of the difference between a conveyor belt that moves at a fixed speed (traditional automation) and an AI agent that dynamically adjusts the speed of that belt, predicts maintenance on its motor, and reroutes products to a different line if a bottleneck forms upstream. It moves from execution to management.

The Core Capabilities of Industrial AI Agents

In practice, these agents bring several transformative capabilities to the U.S. factory floor:

- Predictive and Prescriptive Maintenance: Instead of following a fixed maintenance schedule or waiting for a machine to break, AI agents analyze real-time sensor data (temperature, vibration, acoustics) to predict equipment failures with startling accuracy. At Nunar, we’ve deployed agents that have helped clients reduce unplanned downtime by up to 28% . The system doesn’t just flag a problem; it can prescribe the specific maintenance needed and even automatically generate a work order.

- Self-Optimizing Production Lines: AI agents continuously analyze production data to identify inefficiencies. They can autonomously adjust machine parameters for optimal energy consumption, reduce material waste by enhancing precision, and re-sequence operations to improve overall equipment effectiveness (OEE). This directly addresses the growing focus on sustainability and energy efficiency in U.S. manufacturing .

- Autonomous Quality Control: Using advanced machine vision, AI agents can inspect products at a speed and accuracy impossible for the human eye. They learn to identify subtle defects that might escape traditional vision systems, ensuring consistently high quality and dramatically reducing scrap and rework costs.

New Metrics for a New Era: Measuring AI Agent Success

As AI agents take on more complex roles, the old key performance indicators (KPIs) like simple task completion rates are no longer sufficient. A fast agent isn’t necessarily an efficient or intelligent one. To truly gauge the ROI of your AI investment, U.S. manufacturers need to adopt a new set of metrics designed for autonomous systems .

Table: Next-Generation Metrics for AI Agent Performance

Based on our work deploying over 500 agents, we’ve found that the most successful U.S. manufacturers don’t just track these metrics in isolation. They tie them directly to business outcomes like overall equipment effectiveness (OEE), total cost of ownership, and customer satisfaction scores. For example, an improvement in the Autonomy Utilization Ratio should correlate directly with a reduction in labor costs for a specific process and an increase in throughput.

⚙️ Not Sure Which Automation Solution Fits Your Factory?

Book a free session with our AI and industrial automation experts to design a custom roadmap for your operations.

👉 Book a Free 20-Minute Strategy CallA Blueprint for Success: Implementing AI Agents in U.S. Manufacturing

The journey to integrating AI agents isn’t just a technology install; it’s an organizational shift. From our extensive experience, successful implementation follows a clear, phased path.

Step 1: Pinpoint the High-Impact, High-ROI Use Case

Don’t try to boil the ocean. The best starting point is a well-defined process that is repetitive, data-rich, and plagued by variability or high costs. Common starting points we recommend include:

- Predictive Maintenance: Start with your most critical and expensive assets. The ROI is often quick and dramatic .

- Quality Control: Especially in industries like food and beverage, automotive, or electronics where visual inspection is paramount.

- Supply Chain and Inventory Management: Agents can autonomously track inventory levels, predict demand, and even place orders with suppliers.

Step 2: Build the Data Foundation

AI agents are powered by data. This step involves ensuring you have the necessary sensor infrastructure on your equipment and that data from your PLCs, SCADA, and MES systems can be reliably fed into a centralized data platform. The old adage “garbage in, garbage out” has never been more true. Data quality is non-negotiable.

Step 3: Develop and Train the Agent with Domain Expertise

This is where the magic happens. Our development process at Nunar involves deep collaboration with your process engineers and line operators. Their tacit knowledge is invaluable for training the AI on what a “good” versus “bad” outcome looks like and for establishing the operational guardrails within which the agent must operate. This collaborative approach is the best defense against the “black box” problem and ensures the agent’s actions are explainable and trusted by your team.

Step 4: Deploy with a Human-in-the-Loop

Even the most advanced AI agent needs oversight at first. We advocate for a human-in-the-loop model, especially in the early stages . The agent acts, but its decisions are monitored and can be overridden by a human expert. This builds trust, provides a crucial safety net, and generates the real-world data needed to further refine the agent’s models.

Step 5: Scale and Evolve

Once the agent has proven its value in one area, the blueprint can be replicated. The platform you’ve built can be used to scale AI agent deployment across other lines, shifts, and even entire facilities.

Real-World Impact: AI Agent Case Studies in U.S. Manufacturing

The theory is compelling, but the proof is in the production data. Here are two anonymized examples from our portfolio that illustrate the tangible impact of AI agents.

Case Study 1: From Reactive to Predictive in Automotive Parts

A major Tier 1 automotive supplier was facing costly unplanned downtime on their high-speed stamping presses. A failure could halt multiple customer assembly lines, resulting in six-figure penalties.

- Solution: We deployed an AI agent integrated with vibration, thermal, and power quality sensors on their most critical press. The agent was trained on historical failure data and continuously learned the unique “fingerprint” of healthy versus failing operation.

- Outcome: The agent successfully predicted a critical bearing failure 52 hours before it would have caused a catastrophic breakdown. The maintenance team was scheduled, the part was replaced during a planned break, and zero production was lost. This single event saved an estimated $250,000 in downtime and emergency repair costs.

Case Study 2: Optimizing for Sustainability in Food & Beverage

A large food processing plant was under pressure to reduce its energy consumption and environmental footprint. Their energy usage was highly variable and poorly understood.

- Solution: An AI agent was deployed to monitor and control their complex refrigeration and steam systems. The agent didn’t just run equipment at fixed setpoints; it learned the thermal dynamics of the entire plant and dynamically adjusted equipment settings based on real-time production schedules and ambient weather conditions.

- Outcome: The system achieved a 15% reduction in energy consumption for the controlled systems, translating to over $1 million in annual savings. Furthermore, it significantly reduced the plant’s carbon emissions, providing a powerful story for both corporate sustainability reports and cost-conscious leadership.

Navigating the Hurdles: Challenges and Considerations

The path to AI-driven autonomy is not without its obstacles. Being aware of these challenges is the first step to overcoming them.

- The Integration Hurdle: Many U.S. factories are a patchwork of legacy equipment and modern systems. Integrating new AI agents with decades-old PLCs and proprietary protocols can be a technical challenge. This is where working with a partner with deep industrial integration experience is critical.

- The Data Quality Imperative: An AI agent is only as good as the data it receives. Inconsistent, incomplete, or “dirty” data from factory floor sensors is a common roadblock. A rigorous data governance and cleansing process is a prerequisite for success.

- The Human Factor and Change Management: Employees may fear that AI agents will make their jobs obsolete. Proactive change management is essential. At Nunar, we’ve found that positioning AI agents as tools that augment human workers—freeing them from mundane tasks for higher-value problem-solving—is the key to gaining buy-in. Upskilling your workforce is not a side effect; it is a core requirement .

- Trust and Explainability: For operators to trust an AI agent’s decision, they need to understand the “why.” Developing agents that can provide clear, explainable reasoning for their actions is a key focus of our development process and is crucial for widespread adoption.

The Future of U.S. Manufacturing is Agentic

Looking forward, the convergence of AI agents with other technologies will unlock even greater potential. We see the rise of “agents of agents,” where a master AI agent orchestrates the work of multiple specialized sub-agents across the entire supply chain. The integration of 5G technology will provide the ultra-low latency and reliability needed for massive, wireless sensor networks and real-time agent control . Furthermore, the principles of Green AI will ensure that these powerful systems are themselves optimized for minimal energy consumption .

The transformation of U.S. manufacturing is underway. The leaders of this new era won’t be the companies with the most machines, but the ones with the most intelligent and adaptive operations. By strategically deploying AI agents, you can build a factory that is not only more efficient and profitable but also more resilient and competitive on the global stage.

People Also Ask

Traditional automation relies on pre-programmed, rigid rules to execute repetitive tasks, while AI-powered automation uses intelligent agents that can perceive their environment, learn from data, and make autonomous decisions to optimize complex workflows and adapt to changing conditions

While timelines vary by project complexity, many of our U.S. manufacturing clients see a clear return on investment within 6 to 12 months post-deployment, driven by reductions in unplanned downtime, lower labor costs, and improved product quality and throughput.

Yes, absolutely. Modern AI agents are designed with robust safety protocols and human-in-the-loop oversight models. They excel at handling dangerous, repetitive, or ergonomically challenging tasks, which in turn creates a safer work environment and allows human workers to focus on more cognitive and strategic activities .

The most successful first step is to conduct a process audit to identify a specific, high-impact pain point—such as unexpected machine failures or quality inconsistencies. This focused approach allows for a manageable project scope and a clear, demonstrable proof of concept.

NunarIQ — The All-in-One AI Agent Platform Driving Efficiency, Precision, and Growth

NunarIQ equips GCC enterprises with AI agents that streamline operations, cut 80% of manual effort, and reclaim more than 80 hours each month, delivering measurable 5× gains in efficiency.

Industries

- Logistics

- Retail

- Manufacturing

- Healthcare

- Finance

- Energy & Resources

Resources

- Blogs

- Whitepaper

- Knowledge Base

- AI Agent Requirement Analysis