Table of Contents

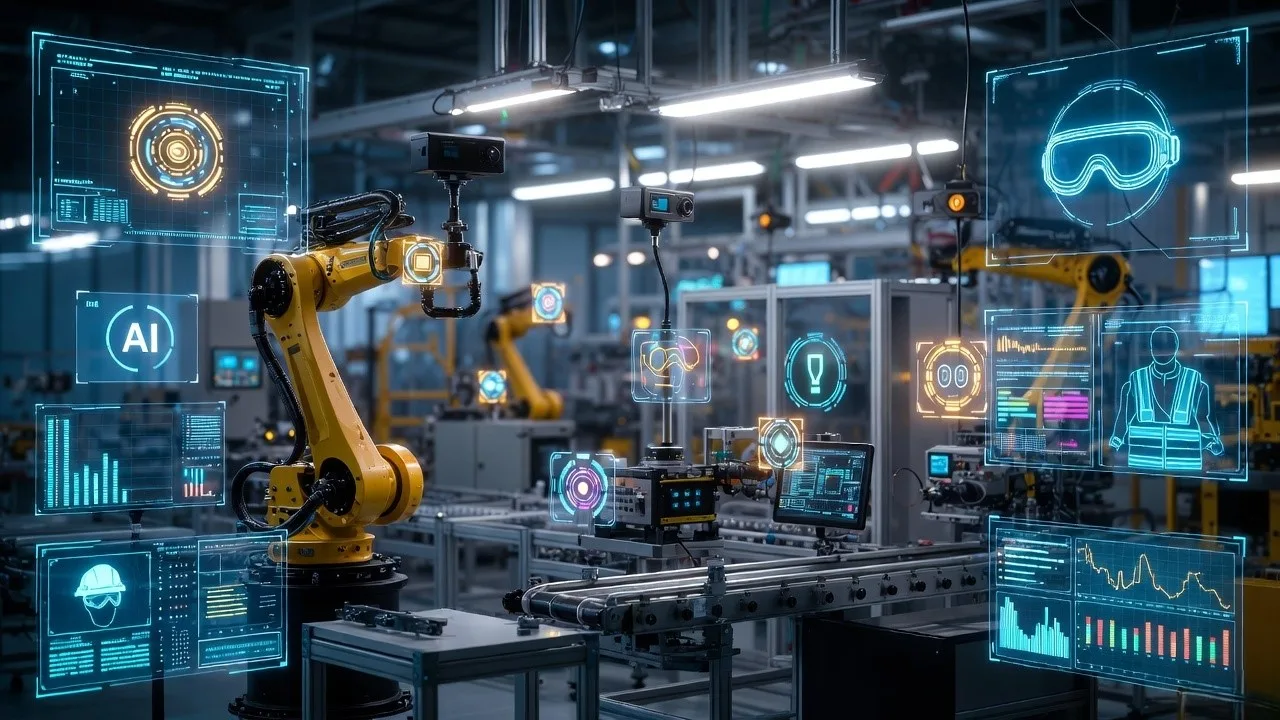

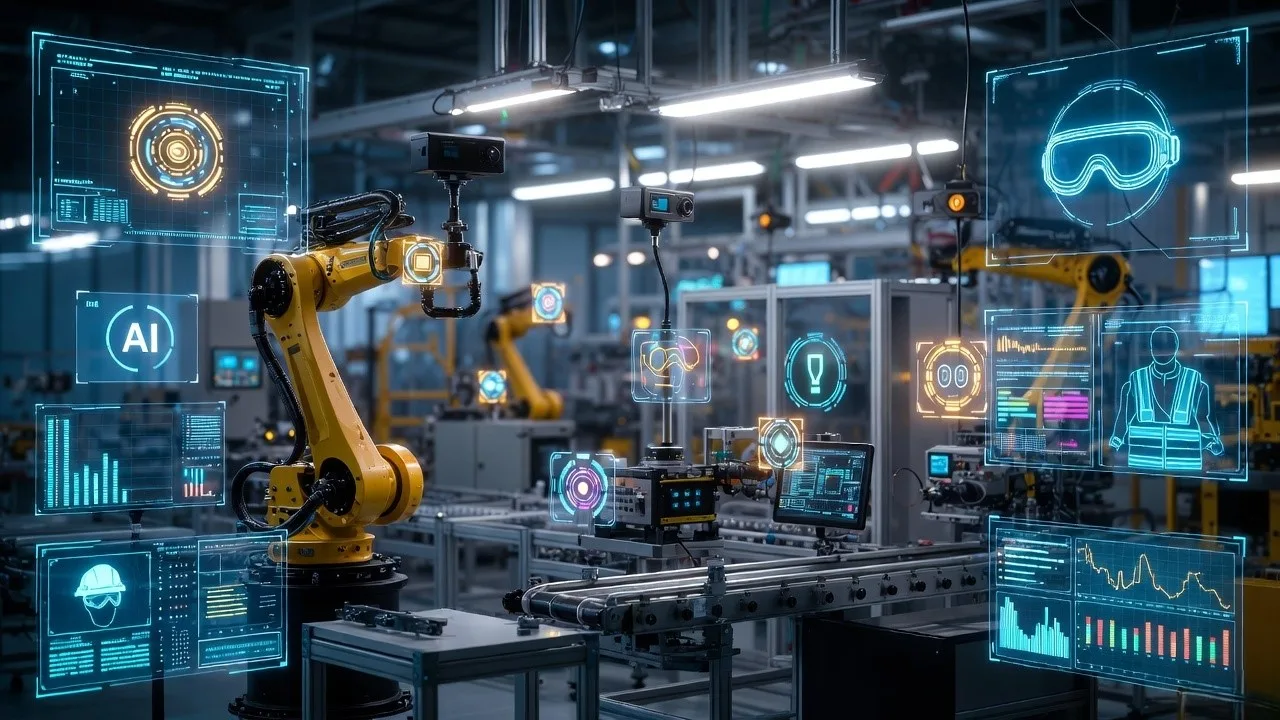

PPE Detection with AI Video Analytics: The Future of Workplace Safety

Personal Protective Equipment (PPE) is a non-negotiable part of workplace safety, especially in sectors like manufacturing, construction, mining, and logistics. Yet even the most well-defined safety protocols depend on consistent human compliance and that’s where mistakes happen.

AI-driven video analytics is changing this dynamic. It allows companies to detect PPE compliance in real time, reduce manual supervision, and prevent costly incidents before they occur.

This article explores how AI-based PPE detection systems work, what they offer to safety managers and operations heads, and how enterprises can implement them for measurable ROI.

Why PPE Monitoring Needs Automation

Traditional PPE monitoring relies on manual observation either by supervisors or through retrospective camera reviews. Both methods are slow, inconsistent, and prone to human error.

Even a single missed detection a worker entering a high-risk zone without a helmet or reflective vest can lead to severe injury, downtime, or compliance penalties.

AI video analytics changes this by using computer vision models that identify PPE items in live video feeds, flag violations instantly, and record event data for reporting.

What Is PPE Detection with AI Video Analytics?

At its core, a PPE detection system is a combination of:

- CCTV or IP camera networks feeding live video data.

- AI video analytics software trained to recognize safety gear like helmets, vests, gloves, boots, and masks.

- Edge or cloud-based computing that processes frames in real time.

- Alerting and dashboard systems that notify supervisors when non-compliance is detected.

Example in Action

Imagine a factory floor equipped with existing cameras. When a worker enters a restricted zone:

- The AI model detects their presence.

- It checks for required PPE items (say, helmet and high-visibility jacket).

- If either item is missing, an alert is sent to the safety control room or a mobile device.

- The event is logged with time, camera ID, and image evidence.

No additional human effort required and every potential risk gets documented automatically.

How AI PPE Detection Works

- Object Detection Models: Deep learning algorithms (often built on frameworks like YOLOv8, ResNet, or EfficientDet) are trained on thousands of labeled images of workers with and without PPE.

- Real-Time Video Processing: The system analyzes video frames continuously, identifying humans and checking whether required PPE items are present.

- Rule-Based Logic: Custom rules define what’s mandatory in each area e.g., “Helmet + Vest” in Zone A, “Gloves + Mask” in Zone B.

- Alerts and Reporting: Violations trigger notifications via SMS, email, or integrated safety dashboards. Reports are automatically compiled for audits and compliance.

- Integration with Existing Systems: Most platforms integrate with existing video management systems (VMS) and safety management software, so enterprises don’t need to rebuild infrastructure.

Key Features of AI-Driven PPE Detection

- Multi-PPE Identification: Detects helmets, gloves, vests, goggles, masks, and safety shoes simultaneously.

- Custom Rule Configuration: Different areas can have different PPE requirements.

- Zone-Based Detection: Defines high-risk and restricted zones for focused monitoring.

- Event Playback & Evidence Logs: Stores clips and images of violations for investigations.

- Real-Time Alerts: Immediate notifications via SMS, app, or email.

- Integration Ready: Works with existing CCTV and enterprise systems.

- Scalable Deployment: From a single site to multiple plants across geographies.

Benefits for Enterprises

1. Reduced Incidents and Injuries

AI eliminates blind spots in human monitoring, preventing accidents before they happen.

2. Automated Compliance Reporting

No need for manual checklists. The system documents every incident with timestamps and visual proof.

3. Higher Accountability

Supervisors can see compliance trends and take corrective action based on data, not guesswork.

4. Operational Efficiency

Automated alerts save time for safety teams and let them focus on preventive measures instead of monitoring feeds.

5. Data-Driven Insights

Dashboards reveal non-compliance patterns by shift, zone, or worker group — helping refine training and SOPs.

6. Integration with Workforce Management

AI analytics can link with attendance or access control systems, restricting entry to workers without PPE.

7. Strong ROI

Fewer incidents mean lower insurance premiums, less downtime, and improved brand reputation.

Use Cases Across Industries

Manufacturing Plants

Monitor factory floors for PPE compliance during machine operation or hazardous material handling.

Construction Sites

Detect missing helmets, vests, or boots in real-time across large, open environments.

Oil & Gas Facilities

Track compliance in restricted and explosion-prone zones where PPE rules are critical.

Warehousing & Logistics

Ensure forklift operators and dock workers wear reflective vests and gloves.

Mining Operations

Monitor remote or underground areas where human supervision is difficult.

Integration with AI Agent Platforms

Companies like Nunar, specializing in AI agent-based automation, can take PPE detection further — integrating it with your organization’s broader safety and operations ecosystem.

For example:

- AI agents can analyze violation trends, correlate them with shift data, and suggest preventive actions.

- They can automate compliance reporting to EHS systems.

- They can trigger workflows, such as restricting access until safety conditions are restored.

This combination of video analytics + AI agents turns reactive monitoring into proactive risk management.

Implementation Steps for Enterprises

- Site Assessment – Evaluate camera coverage, lighting, and field of view.

- PPE Definition – Define what equipment is mandatory for each zone.

- Model Training/Calibration – Fine-tune AI models for local conditions and uniforms.

- Integration – Connect with CCTV, IoT sensors, and safety dashboards.

- Pilot Phase – Start small (1-2 critical zones) to refine performance.

- Rollout – Scale to additional locations or plants.

- Continuous Learning – Update models as new PPE types or uniforms are introduced.

Challenges and Considerations

- Lighting and Visibility: Poor lighting or camera angles can reduce accuracy.

- Model Adaptability: Models must be retrained when uniforms, helmets, or vests change color or shape.

- False Positives: Some detections may be inaccurate; fine-tuning and retraining improve performance.

- Data Privacy: Ensure compliance with video data regulations (GDPR, OSHA standards, etc.).

- Infrastructure Readiness: Reliable network and compute power are essential for real-time analytics.

ROI and Business Impact

Implementing AI video analytics for PPE detection typically results in:

- 30–50% reduction in safety violations within 6 months.

- Up to 70% lower monitoring costs by reducing manual supervision.

- Improved compliance scores in audits.

- Shorter response times during safety incidents.

- Enhanced brand trust due to visible safety commitment.

For large enterprises, these improvements often translate to significant cost savings and improved workforce morale.

The Future of AI in Workplace Safety

The next wave of safety automation goes beyond detection:

- Predictive Analytics: AI agents forecast high-risk zones based on previous incidents.

- Voice and Gesture Recognition: Systems detect distress signals or unsafe gestures.

- Edge AI Cameras: Local processing on devices reduces latency and network load.

- Unified Safety Dashboards: Integration with IoT sensors and environmental monitors for complete site visibility.

In essence, AI is evolving from watching compliance to ensuring it.

Conclusion

AI-based PPE detection is transforming how enterprises approach safety from manual enforcement to intelligent automation.

With AI video analytics, businesses gain real-time visibility, data-driven insights, and consistent compliance across facilities. Partnering with an AI agent development company like Nunar helps extend this capability across broader safety workflows connecting detection with action, and compliance with outcomes.

For organizations serious about zero-incident operations, AI-driven PPE detection is no longer an experiment, it’s a strategic investment in safer, smarter workplaces.

People Also Ask

PPE detection uses AI algorithms to automatically identify if workers are wearing required personal protective equipment through live or recorded video feeds.

It ensures real-time monitoring of compliance, reduces the risk of accidents, and allows immediate corrective actions to maintain safety standards.

Commonly detected items include helmets, safety vests, gloves, goggles, and masks depending on workplace requirements.

PPE detection leverages computer vision, deep learning models, object detection algorithms, and real-time video processing for accuracy.

Yes, it can be integrated with access control, alert systems, and reporting dashboards to provide comprehensive safety management.

NunarIQ — The All-in-One AI Agent Platform Driving Efficiency, Precision, and Growth

NunarIQ equips GCC enterprises with AI agents that streamline operations, cut 80% of manual effort, and reclaim more than 80 hours each month, delivering measurable 5× gains in efficiency.

Industries

- Logistics

- Retail

- Manufacturing

- Healthcare

- Finance

- Energy & Resources

Resources

- Blogs

- Whitepaper

- Knowledge Base

- AI Agent Requirement Analysis